Structural Steel Detailing Services Benefits – Structural Steel Detailing Services Outsourcing Benefits – Structural Drafting Group Steel Detailing Services Benefits

A steel structure is essentially a collection of various components such as columns, beams, floor plates, roof members, and more. These elements are made of steel and come in different sizes and shapes. They are ingeniously connected to each other through welding or bolting techniques. This robust construction method ensures the strength and stability of the entire structure.

Structural steel detailing is a critical step in the construction process that involves creating detailed drawings and models of steel components and connections. This information is essential for fabricators, erectors, and contractors to accurately manufacture and erect steel structures. Here is a breakdown of the process of structural steel detailing:

Project initiation: The process begins with understanding the project requirements, architectural and engineering drawings, specifications, and other relevant documents. The steel detailer collaborates with the project team to establish the scope, timeline, and deliverables.

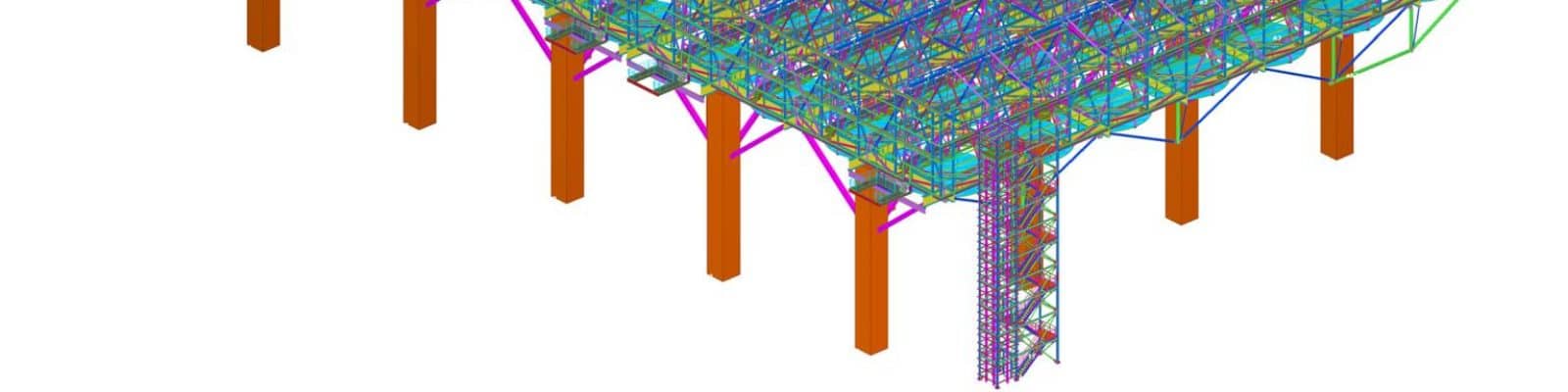

Initial modeling: The detailer creates a 3D model of the steel structure using specialized software. This model serves as the foundation for all subsequent detailing activities. It includes columns, beams, braces, connections, and other structural elements.

Connection design: The detailer designs the connections between different steel members based on engineering calculations and industry standards. This involves determining the type, size, and configuration of bolts, welds, plates, and other connection components.

Detailing of steel members: The detailer generates detailed drawings for each steel member, including columns, beams, trusses, and bracing. These drawings include dimensions, section details, hole sizes, and any necessary fabrication and assembly instructions.

Bill of materials: The detailer prepares a comprehensive bill of materials (BOM) that lists all the required steel components, including sizes, lengths, quantities, and other specifications. This is used by fabricators to estimate material costs and procure the necessary materials.

Shop drawings: The detailer creates shop drawings that provide fabrication instructions to the steel fabricator. These drawings include detailed views, sections, and dimensions of each steel piece, along with information on welding, drilling, cutting, and surface preparation.

Erection drawings: The detailer develops erection drawings that guide the steel erector on how to assemble and install the steel components on the construction site. These drawings include information on the sequence of erection, lifting points, temporary bracing, and other important details.

Coordination with other disciplines: The detailer collaborates with other disciplines, such as architectural and MEP (mechanical, electrical, plumbing) teams, to ensure proper coordination and integration of steel components with other building systems.

Quality control: Throughout the detailing process, the detailer performs quality checks to ensure accuracy, completeness, and compliance with relevant codes and standards. This helps identify and resolve any errors or discrepancies before the fabrication and construction stages.

Delivery of final documentation: Once the detailing is complete, the detailer delivers the final set of drawings and models to the project team. These documents serve as a reference for fabrication, erection, and construction activities.

In summary, structural steel detailing involves creating detailed drawings, models, and documentation to facilitate the accurate fabrication, erection, and construction of steel structures. It is a meticulous process that requires expertise in software tools, engineering principles, and industry standards to ensure the successful realization of the project.

One thought on “The Benefits of Effective Structural Steel Detailing”

Comments are closed.